ECONYL® Nylon

„No waste. No new resources. Just endless possibilities.“

Among the ranks of materials we use, one of the most sustainable fibers that are currently being processed in the textile industry can be found: ECONYL® nylon

Around ten years ago, the Italian company Aquafil developed this 100 percent recycled nylon fiber, thereby consituting a green trend reversal.

In this material, waste replaces the crude oil required for producing conventional nylon. In a specifically developed process powered by renewable energies, used fishing nets, old carpets or industrial waste are converted into ECONYL® fiber. Regenerated nylon that can be recycled and reused an infinite number of times.

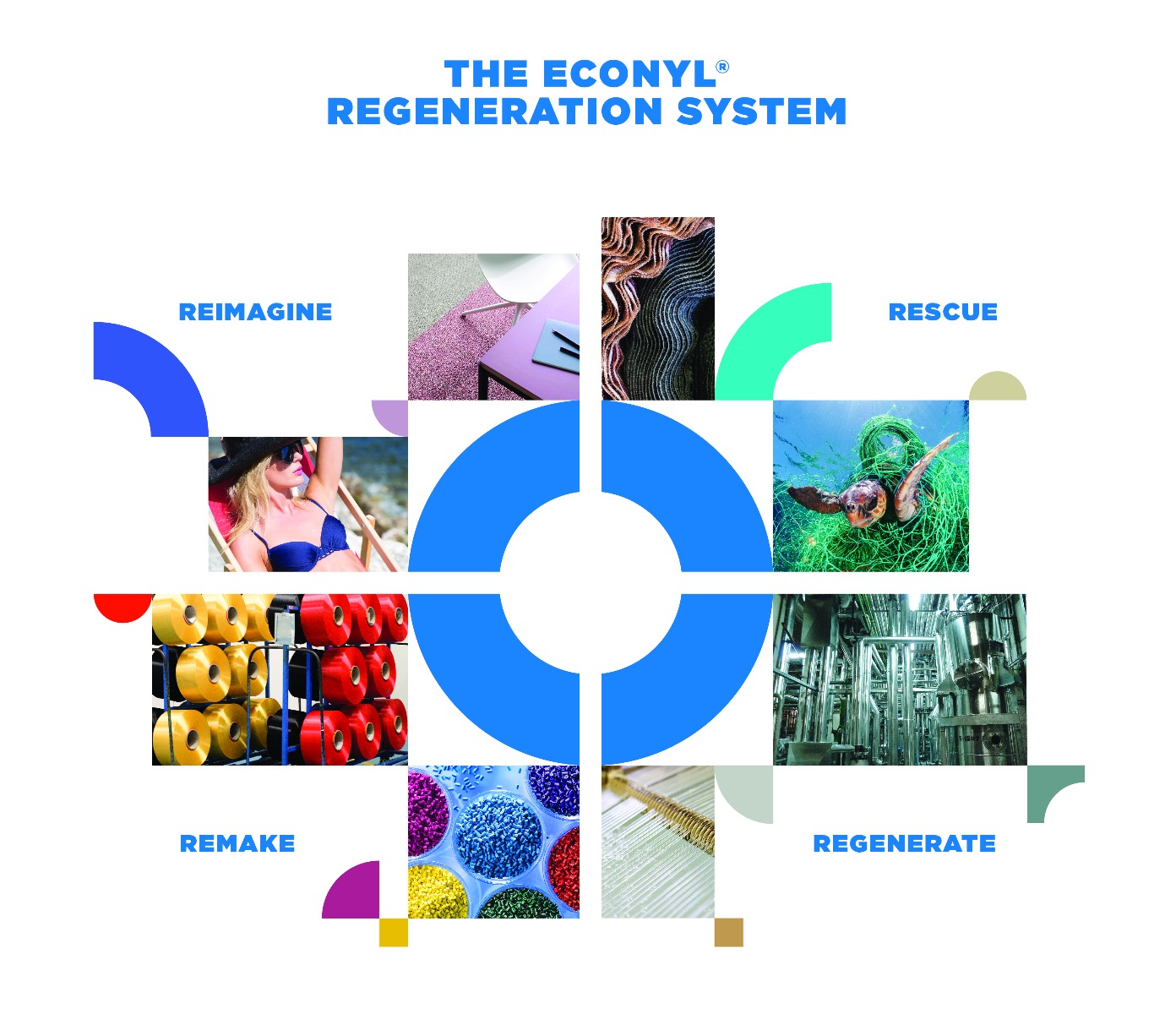

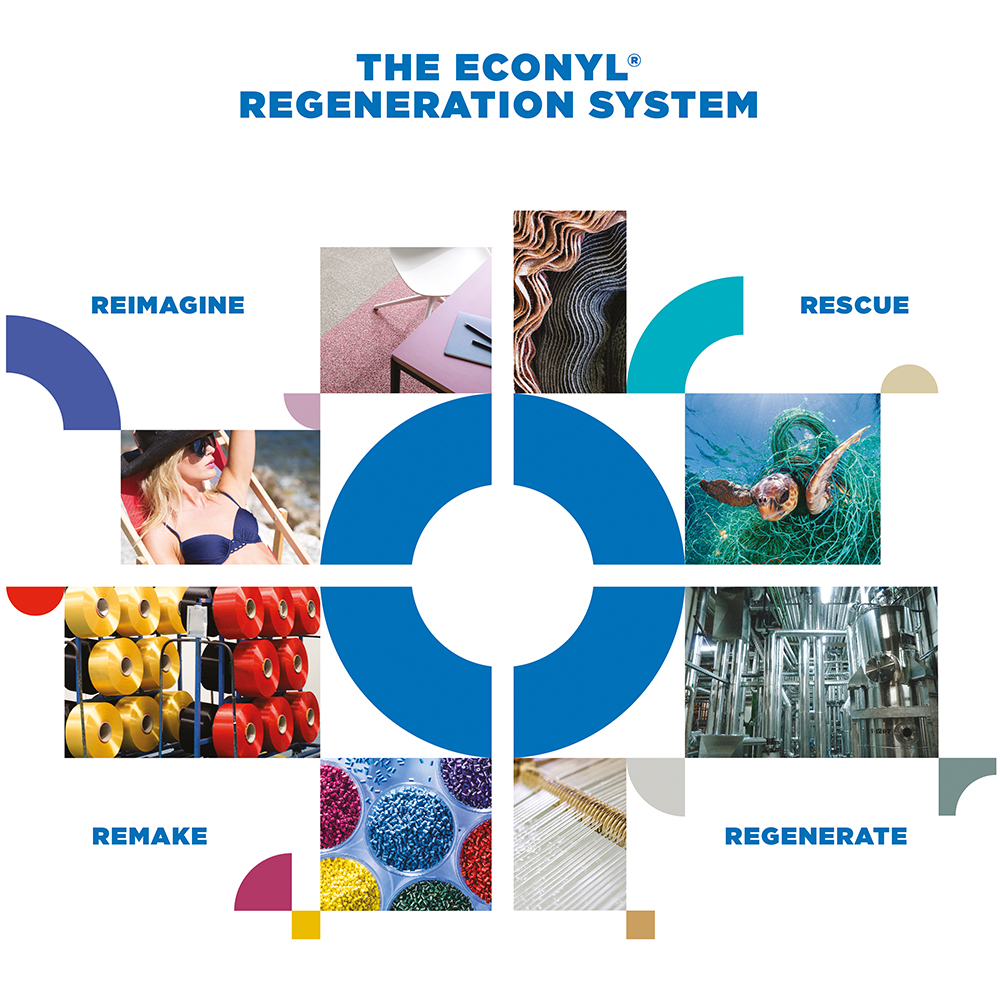

STEP BY STEP

1. Rescue

The ECONYL® Regeneration System starts with the collection of waste from different parts of the world. This ranges from tons of discarded carpets to waste from industrial processes to fishing nets, which are amongst others retrieved from the sea by volunteer divers as part of the “Healthy Seas” initiative.

2. Regenerate

In the course of a chemical regeneration and cleaning process, the nylon waste is recycled back to its original purity. Therefore, ECONYL® nylon is exactly the same as conventionally produced virgin nylon.

3. Remake

The regenerated nylon is processed into carpet yarn and textile yarn for the industries.

4. Reimagine

Carpet manufacturers and fashion brands such as HÖGL use it to create new and environmentally friendly products. We have set ourselves the goal of replacing conventionally produced nylon in our products with ECONYL® fiber. This is how we want to contribute to a closed circular economy.

So what exactly is it that makes ECONYL® yarn so sustainable? When working with ECONYL® nylon, sustainability comes into its own in different forms, starting with the innovative solution for reducing waste or rather processing it. What is more, ECONYL® regenerated nylon contributes to a more climate-friendly balance. Reusing nylon to produce the sustainable material reduces the global warming impact of nylon by 90 percent compared to the material made from oil. In terms of quality, ECONYL® fiber is in no way inferior to conventional nylon. Even better: ECONYL® yarn can be recycled and reshaped - over and over again without losing quality.

In accordance with our commitment to a more sustainable industry, ECONYL® nylon can also be found in our shoes. In addition to leather, which has been certified with the Gold Rating of the Leather Working Group, it is used as upper material in our HÖGLVISION models.