Craftsmanship meets Innovation

85 years of Högl - 85 years of craftsmanship and creativity

Högl shoes are synonymous with comfort, craftsmanship and tradition. But what production processes do our high-quality shoes have to go through before they’re ready to be the perfect fit? And what faces are hiding behind our beloved products? In an interview with technical team leaders Daniel Fuchs and Johannes Hartinger, we take a look behind the scenes of Högl HQ and show how 85 years of Austrian craftsmanship combined with innovative technologies are the secret to ensuring maximum wearability.

„A Högl shoe stands out from the crowd, above all because it combines modern style, maximum comfort and the highest quality materials.“

Hello Daniel and Johannes. Thank you for agreeing to speak to us. You’re both technical team leaders at Högl: what exactly do your roles entail?

Johannes: My work mostly involves the shoes’ upper. This means anything from constructing the first prototype, developing the pattern, creating production specifications as well as guaranteeing quality standards throughout the entire development process.

Daniel: In our work developing the shoe base technically, we’re responsible for constructing and putting together the shoe components like the sole, heel and last. We follow these components on their journey from initial sketch to their release in stores.

Can you briefly tell us about your education as well as your career so far?

Johannes: Before I started my career, I spent 5 years at the HTL in Andorf studying Plastic and Environmental Technology.

At Högl, I began my training in shoe manufacture, before I started working in technical development as a modeller.

Daniel: After HTL Andorf, I started my working life at Högl. I also completed training in shoemaking and finishing.

I have always worked in the department responsible for the base of the shoes. At first, constructing heels and soles, then later on, I was put in charge of developing shoe lasts.

Johannes: We have been the team leaders of our respective departments for two years.

„Traditional craftsmanship plays a huge role in our shoe production.“

What processes do the shoe designs go through at Högl?

Johannes: Firstly, all the separate parts of a shoe are cut out of their respective materials. After this, the parts are stitched together to create the upper. During assembly, first the upper is clipped onto the last and the inner sole, and then the sole is attached to the heel. Finally, the cover sole is inserted and the shoe is given a finish, according to the material.

What is the significance of traditional craftsmanship in how the shoes are produced? To what extent does it tie into innovation and modern technologies?

Daniel: Traditional craftsmanship plays a huge role in our shoe production. Many of the processes are carried out by hand to ensure the highest quality. This is largely due to the fact that we work a lot with leather, which requires a lot of experience and a feel for the material.

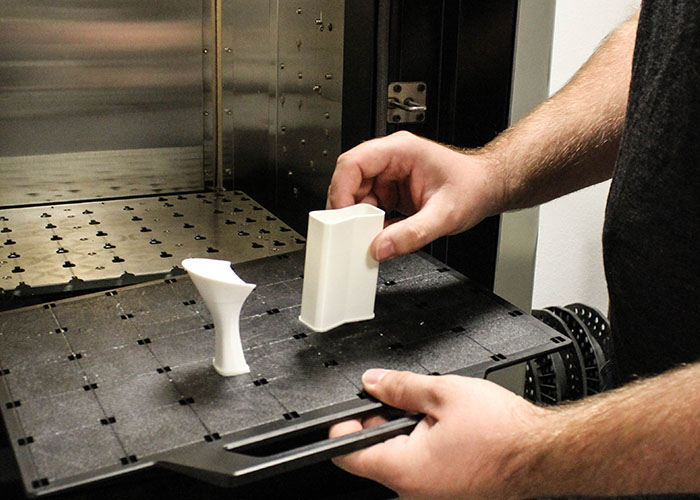

The interplay with modern technologies begins at the development stage. 3D scanners and 3D printers as well as 3D construction technology are essential for this process.

„Many of the processes are carried out by hand to ensure the highest quality.“

What stands out about a Högl shoe, in terms of quality? What does a shoe’s technical development depend on?

Johannes: A Högl shoe stands out from the crowd, above all because it combines modern style, maximum comfort and the highest quality materials.

Daniel: Exactly! That’s why, even at the development stage, each shoe goes through several quality checks, where as much attention as possible is paid to these signature characteristics.